In the world of electric motors, a true engineering marvel has emerged: the Brushless Direct Current (BLDC) motor. These sophisticated devices have revolutionized numerous industries with their efficiency, precision, and reliability. In this blog, we’ll explore the fascinating world of BLDC motors, diving into their inner workings, applications, and the transformative impact they have had on various fields.

The Inner Workings of a BLDC Motor

At its core, a BLDC motor is a type of electric motor that operates on the principles of electromagnetic induction. What sets it apart from its brushed counterparts is the absence of physical brushes and a commutator. Instead, it relies on electronic commutation through a controller.

Here’s a simplified breakdown of how it works:

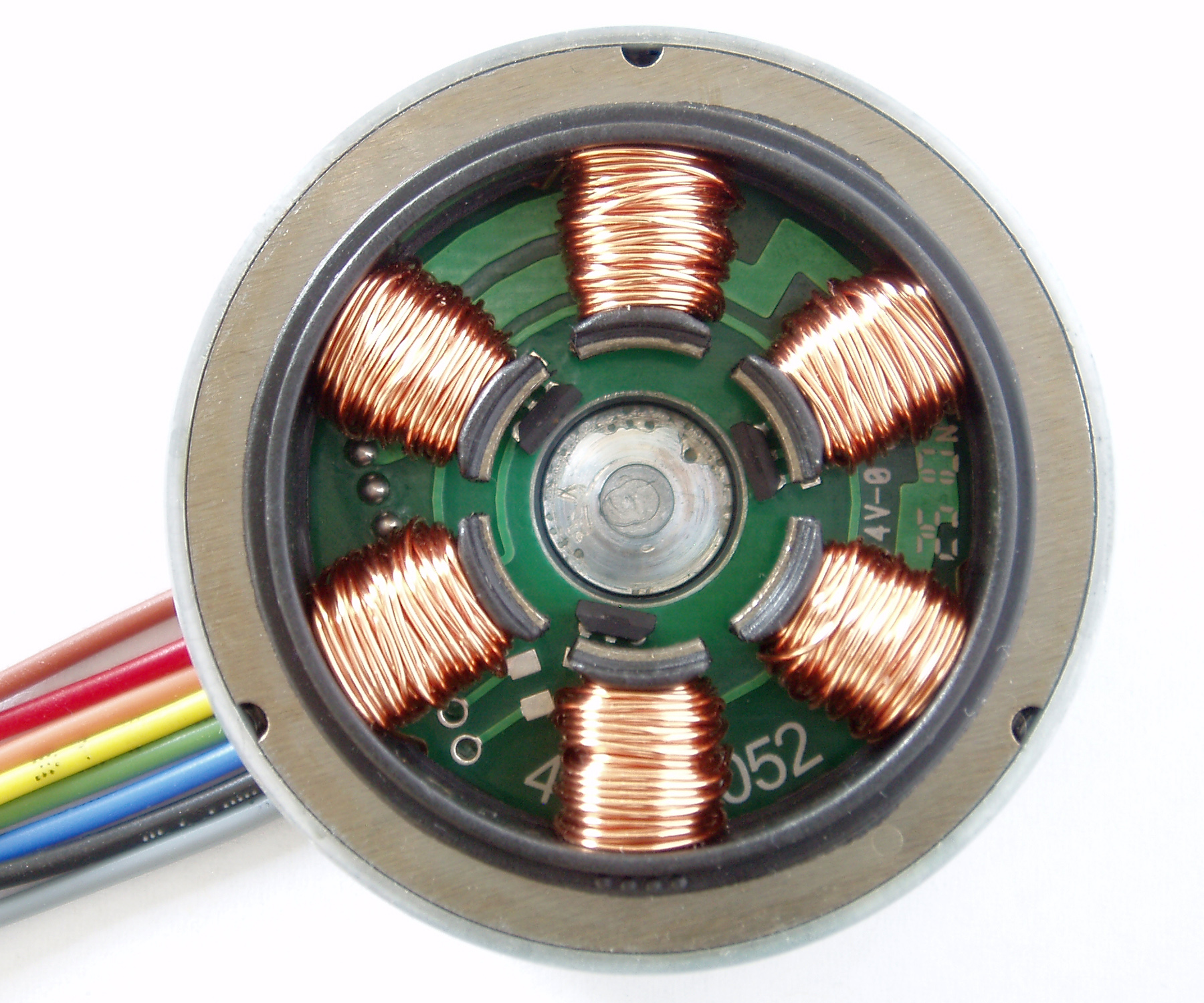

- Stator: The stator of a Brushless Direct Current (BLDC) motor is a crucial component that forms the stationary part of the motor. Typically constructed as a cylindrical core with windings made of copper or aluminum wire, the stator generates a rotating magnetic field when energized by an external power source. This magnetic field interacts with the rotor, inducing motion. Unlike brushed motors, BLDC motors do not have brushes on the stator, leading to less friction and wear. The stator windings are strategically placed and energized in a sequence controlled by an electronic commutation system, ensuring precise timing and efficiency in the motor’s operation. The stator’s design and the quality of its winding play a significant role in determining the motor’s performance, efficiency, and overall reliability in various applications, from consumer electronics to industrial machinery.

Stator of a BLDC motor

- Rotor: The rotor of a Brushless Direct Current (BLDC) motor plays a pivotal role in its operation, serving as the moving component within the motor assembly. In a typical BLDC motor, the rotor consists of permanent magnets that generate a magnetic field. Unlike traditional brushed motors, the rotor in a BLDC motor is not equipped with winding coils. Instead, the stator, which surrounds the rotor, contains the winding coils. The interaction between the magnetic field of the rotor and the stator’s coils, controlled by electronic commutation, drives the rotation of the rotor. This design eliminates the need for physical brushes, resulting in reduced friction, wear, and maintenance issues. The construction of the rotor is crucial for the motor’s efficiency and performance, making use of durable and powerful permanent magnets to ensure a reliable and long-lasting operation in various applications, from consumer electronics to industrial machinery.

Rotor(Left side) of a BLDC motor

- Electronic Commutation: Electronic commutation is a fundamental aspect that distinguishes Brushless Direct Current (BLDC) motors from their brushed counterparts. In BLDC motors, the commutation process, traditionally achieved by physical brushes in brushed motors, is handled electronically. This innovation involves the use of sensors or Hall-effect devices that detect the rotor’s position in real-time. Based on this information, an electronic controller precisely determines when to switch the current in the motor windings, ensuring optimal alignment with the rotor’s magnetic field. This electronic commutation system eliminates the need for brushes, reducing wear and friction. The result is a more efficient and reliable motor with smoother operation. The electronic precision afforded by this commutation method is a key factor in the superior performance and extended lifespan of BLDC motors, making them a preferred choice in various applications demanding high efficiency and reliability.

Efficiency and Performance: Hall Sensors and Sensor-less Operation

BLDC motors can operate in two main modes: with Hall sensors or sensor-less.

- Hall Sensor Operation: The operation of a Brushless Direct Current (BLDC) motor involves intricate control mechanisms, and Hall effect sensors play a pivotal role in this process. Hall effect sensors are strategically positioned within the motor to detect the position of the rotor magnets as they rotate. These sensors operate based on the Hall effect, a phenomenon in which an electric current in a magnetic field generates a voltage perpendicular to the current flow. In the context of a BLDC motor, the Hall effect sensors provide feedback to the motor controller about the precise position of the rotor. This information allows the controller to synchronize the application of power to the motor coils, ensuring optimal timing for each phase. By dynamically adjusting the timing and sequence of the electromagnetic pulses, the Hall effect sensors contribute to the seamless and efficient operation of the BLDC motor, enabling precise control over speed, torque, and direction.

Hall effect sensors connected to the circuit via three group of three blue wires in a BLDC motor

- Sensor-less Operation: Sensorless operation of a Brushless Direct Current (BLDC) motor represents a technological advancement that eliminates the need for position sensors, such as Hall effect sensors, for rotor position feedback. Instead of relying on external sensors to determine the rotor’s position, sensorless BLDC motors employ sophisticated algorithms and the back electromotive force (EMF) generated by the motor windings. By analyzing the voltage waveforms, the motor controller can deduce the rotor’s position in real-time. This innovation streamlines the motor design, reduces complexity, and enhances overall system reliability by eliminating the wear-prone sensors. Sensorless operation is particularly advantageous in applications where minimizing components and increasing robustness are crucial, such as in electric vehicles, home appliances, and various industrial systems.

Sensorless BLDC motor by Torxpower

Advantages of BLDC Motors

- Higher Efficiency: Brushless Direct Current (BLDC) motors stand out in the realm of electric motors due to their higher efficiency. Unlike traditional brushed motors, BLDC motors eliminate the need for physical brushes, resulting in reduced friction, wear, and heat generation during operation. This absence of frictional losses enhances the overall efficiency of the motor. Additionally, BLDC motors employ electronic commutation, optimizing the timing of current flow to the motor coils. This electronic control allows for precise and efficient energy conversion, minimizing energy losses and maximizing the conversion of electrical power into mechanical output. The higher efficiency of BLDC motors not only contributes to energy savings but also translates into improved performance, making them a preferred choice in various applications, from electric vehicles to industrial automation and robotics.

- Improved Reliability: Brushless Direct Current (BLDC) motors offer an enhanced level of reliability compared to their brushed counterparts. The elimination of brushes, which are prone to wear and friction, contributes significantly to the improved reliability of BLDC motors. Without physical contact points, there is minimal wear over time, resulting in extended operational life and reduced maintenance requirements. Moreover, the electronic commutation system in BLDC motors provides precise control over the motor’s operation, minimizing the risk of arcing or sparking. This precise control not only enhances reliability but also ensures smoother and more predictable performance. The overall design simplicity, coupled with advanced control mechanisms, makes BLDC motors a reliable choice for applications where consistent and trouble-free operation is paramount, such as in industrial machinery, robotics, and automotive systems.

- Precise Control: The precise control of Brushless Direct Current (BLDC) motors is a hallmark feature that sets them apart in the realm of electric motors. Unlike traditional brushed motors, BLDC motors rely on electronic commutation, where the timing and sequence of current flow to the motor windings are precisely controlled by an external controller or electronic circuit. This level of control allows for accurate and dynamic manipulation of the motor’s speed, torque, and direction. The absence of physical brushes reduces the mechanical limitations and enables smoother operation with minimal friction and wear. The ability to finely tune and regulate the motor’s performance makes BLDC motors ideal for applications demanding precise control, such as in robotics, drones, and various industrial automation systems. Whether it’s maintaining a constant speed, executing intricate maneuvers, or responding swiftly to changes in load, the precise control of BLDC motors ensures optimal and reliable performance in diverse and demanding settings.

- Compact and Lightweight: The Brushless Direct Current (BLDC) motor’s standout feature lies in its lightweight and compact design. Unlike traditional brushed motors, BLDC motors are inherently more compact as they do not require space for brushes and a commutator. This streamlined design contributes to a reduction in both size and weight, making BLDC motors an ideal choice for applications where space and weight constraints are critical factors. The absence of brushes not only eliminates the need for additional components but also reduces the overall mass of the motor. This inherent lightness and compact nature make BLDC motors particularly well-suited for applications in sectors such as aerospace, electric vehicles, and robotics, where optimizing weight and space utilization is essential for achieving high performance and efficiency.

- Reduced Electromagnetic Interference (EMI): Brushless Direct Current (BLDC) motors exhibit reduced electromagnetic interference (EMI) compared to traditional brushed motors. The absence of physical brushes, which can create electrical noise and generate interference, contributes significantly to minimizing EMI in BLDC motors. Additionally, the electronic commutation system in BLDC motors enables smoother and more controlled transitions between motor phases, reducing the likelihood of abrupt changes in current that can lead to electromagnetic disturbances. This characteristic makes BLDC motors particularly suitable for applications where EMI must be kept at a minimum, such as in sensitive electronic equipment, medical devices, and communication systems. The inherently cleaner operation of BLDC motors, coupled with advancements in control technology, positions them as a reliable solution for environments where mitigating electromagnetic interference is crucial.

Applications: From Drones to Appliances

BLDC motors have found their way into a wide array of applications:

- Drones and RC Vehicles: Brushless Direct Current (BLDC) motors have become integral components in the world of drones and Remote Control (RC) vehicles, transforming the landscape of aerial and remote-controlled technology. The high efficiency, compact design, and reliability of BLDC motors make them ideal power sources for these applications. In drones, BLDC motors drive the propellers, providing the necessary thrust for lift and maneuverability. Their efficient operation ensures longer flight times and improved performance. Similarly, in RC vehicles such as cars, boats, and planes, BLDC motors deliver precise control and enhanced power, contributing to a more dynamic and responsive user experience. The absence of brushes in BLDC motors reduces wear and maintenance, making them well-suited for the demanding and agile requirements of drones and RC vehicles, where lightweight, high-performance components are essential for optimal functionality and enjoyment.

BLDC Motors utilized in drones.

- Home Appliances: Brushless Direct Current (BLDC) motors have found widespread application in home appliances, revolutionizing the efficiency and performance of various devices. These motors are commonly employed in appliances like refrigerators, washing machines, and fans due to their energy efficiency and quieter operation. In refrigerators, BLDC motors power the compressor, providing precise and variable-speed control to optimize cooling and reduce energy consumption. Washing machines benefit from the reliability and durability of BLDC motors in driving the drum and ensuring efficient water drainage. Fans equipped with BLDC motors deliver not only improved energy efficiency but also a quieter and smoother operation compared to traditional motor types. The use of BLDC motors in home appliances aligns with the growing emphasis on energy conservation and enhanced user experience, making these motors integral components in modern, eco-friendly household devices.

- Electric Vehicles (EVs): The use of Brushless Direct Current (BLDC) motors in electric vehicles (EVs) has become increasingly prevalent, marking a pivotal shift in the automotive industry toward greater efficiency and sustainability. BLDC motors offer several advantages in the context of electric vehicles, including higher efficiency, reduced maintenance, and enhanced performance. The absence of brushes in BLDC motors eliminates friction and wear, leading to a longer operational life and lower maintenance costs. The precise electronic commutation in BLDC motors allows for efficient energy conversion, contributing to the overall energy efficiency of the electric vehicle. Additionally, BLDC motors provide a compact and lightweight solution, crucial for the design considerations in electric vehicles aiming for improved range and energy utilization. The integration of BLDC motors in electric vehicles represents a crucial step in the ongoing transition toward cleaner and more sustainable transportation solutions.

- Industrial Automation: Brushless Direct Current (BLDC) motors have become integral components in industrial automation due to their numerous advantages. The high efficiency and reliability of BLDC motors make them well-suited for demanding industrial applications. Their precise control, achieved through electronic commutation, allows for accurate speed and torque regulation, enabling seamless integration into various automation processes. BLDC motors are often employed in tasks such as conveyor systems, robotic arms, and CNC machinery, where precision, consistency, and reliability are crucial. The absence of brushes reduces maintenance needs, enhancing the overall uptime of industrial automation systems. Additionally, the compact design and scalability of BLDC motors make them versatile for different industrial settings, contributing to the efficiency and productivity of automated processes across diverse manufacturing sectors.

In conclusion, Brushless Direct Current (BLDC) motors represent a technological leap in electric motor design. Their efficiency, reliability, and precise control have made them a cornerstone of numerous industries, from aerospace to household appliances. As technology continues to advance, the applications of BLDC motors are poised to expand even further, promising a future where efficiency and precision are paramount in all facets of our lives.

Thank you for reading this post, don't forget to subscribe our Youtube Channel.